An Overview of Refractory Ceramic Fibers

This lightweight and versatile material offers easy handling, high temperature tolerance, and cost-saving options

the products made from RCF wools are most important for thermal-processing installations and industrial furnace construction and insulation. The RCF products are lightweight and easy to handle, with high temperature capabilities, good thermal shock and chemical resistance, and low thermal conductivity and heat loss. They are generally used in commercial applications requiring lightweight insulation that is capable of withstanding high temperatures, such as furnace and kiln insulation, fire protection, and automotive exhaust systems.

RCF products are used in high-temperature applications in many industries including metals processing, heat treating, glass and ceramics, chemical and petrochemical, automotive, aerospace, power generation, and even domestic appliances.

The maximum service temperature of different RCFs varies in different atmospheres. Complete replacement of dense refractories with an RCF product form provides the most savings in this regard. Using RCF as backup insulation or as a hot-face veneer over an existing refractory lining, however, affords significant energy savings as well.

Various types of RCF

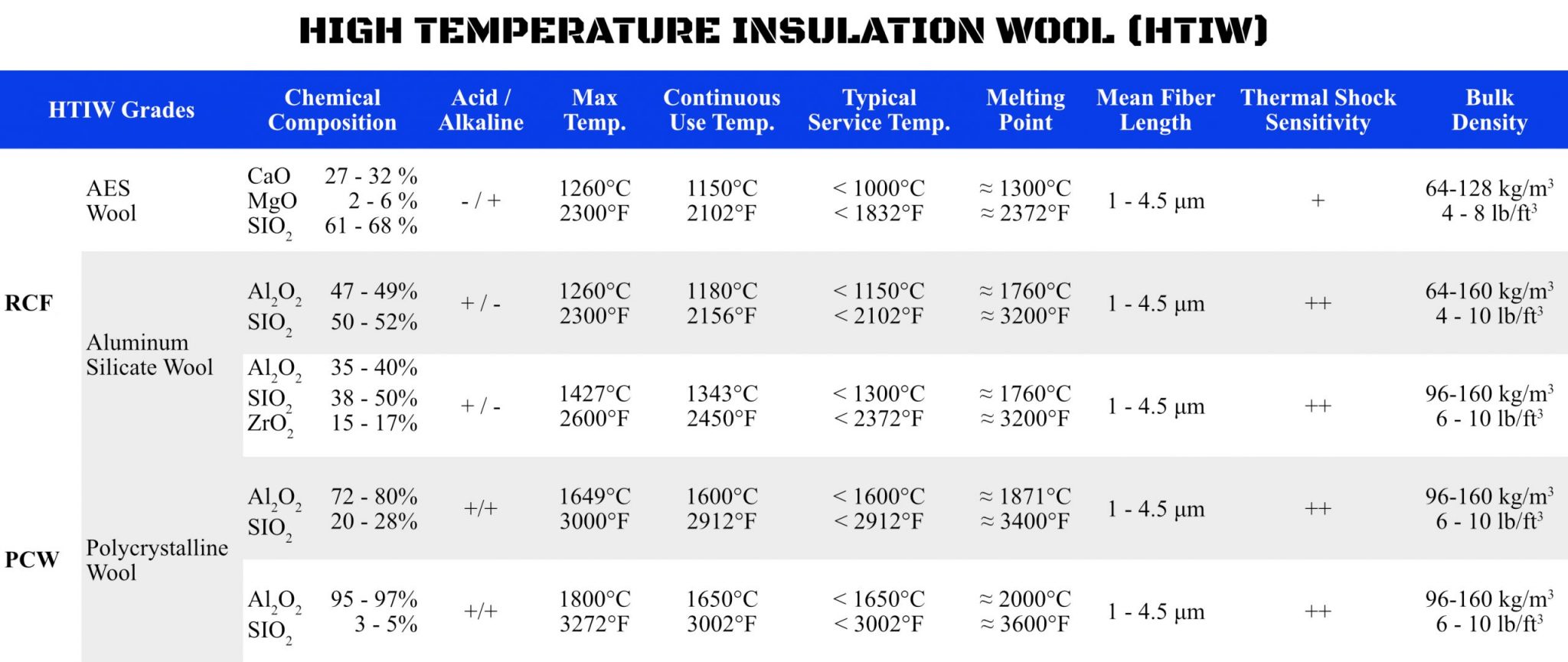

Refractory ceramic fibers are synthetic fibers produced by the melting and blowing or spinning of calcined kaolin clay or a combination of alumina (Al2O3), silicon dioxide (SiO2), or other oxides, usually in a 50:50 weight ratio. The most common grade RCF fiber provided by most USA-based fabricators and suppliers is the “high purity” grade having a temperature rating of around 1,260°C max or 1,180°C continuous use.

There is a higher temperature grade RCF containing about 15 percent ZrO2 with improved temperature rating of about 1,427°C max or about 1,343°C continuous use for the most common zirconia grades. Pricing for this grade is a bit higher than the standard high purity grade.

A biosoluble RCF grade is called AES wool (alkaline earth silicate), consisting of amorphous fibers produced by melting a combination of CaO, MgO, and SiO2. AES fiber products having a temperature rating of around 1,260°C max or 1,150°C continuous use, not quite as high as the standard high purity RCF. The calcium and magnesium oxide content are easier for the body and lungs to dissolve, so called biosoluble.

Products made of AES exhibit lower chemical resistance and are more prone to recrystallization, thereby limiting their potential application in thermal-process engineering. The main application for these AES materials is in the domestic appliance industry and in industrial processes for temperatures to a maximum of 1,100°C, although rated for 1,150°C continuous.

Polycrystalline wools (PCWs) are a higher temperature RCF, consisting of fibers with an Al2O3 content above 63 wt. percent and a SiO2 content under 37 wt. percent. Most suppliers produce the PCWs fiber by aqueous spinning solutions in the sol-gel method. The sol-gel-derived green fibers formed initially as a precursor are then crystallized by means of heat treatment and then handled much like standard RCF and AES fibers. Polycrystalline fiber wools have a max temperature rating of around 1,800°C max and 1,650°C continuous use.

.